Forging

The Company has 2 Drop Forging Hammers of 0.5 T to 3 T capacity. A Counter Blow Hammer of 6.3 T Capasity is under installation and with the addition of this hammer, we shall be able to do forgings from 0.250 kg to 250 kg weight. Forgings are as per customers requirements.

Machining

Machining is done both on conventional as well as CNC machines depending upon customer's requirement and variety of components. CNC Machining Centres prove helpful to precisely do the jobs exactly as per specifications and are backed by latest CAD/CAM Softwares.

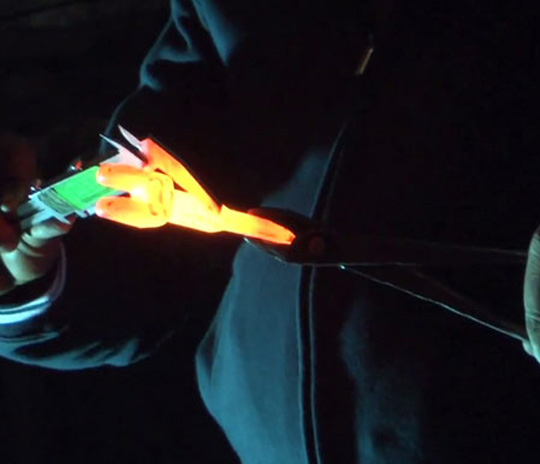

Casting

We have Induction Furnace of 2000 Kg capacity along with latest No-Bake Technology for Sand Molding. The casting molds are hardened through mixture of Resins and Catalysts without heating thereby avoiding Porosity and ensuring smooth surface and Defect Free Castings.

Heat Treatment

We have a Continuous Heat Treatment Plant consisting of pusher type Austenetising and Transformation Furnace with recirculating fans and controlled Cooling Chamber.

Quality Assurance & Testing

Quality Department backed by latest machinery for Chemical analysis, Ultrasonic testing, Tensile & yield testing, Hardness testing, Magnetic particle inspection and dimensional inspection.

Packaging